CoolGuard® Proven Primary/Secondary Containment Geomembranes

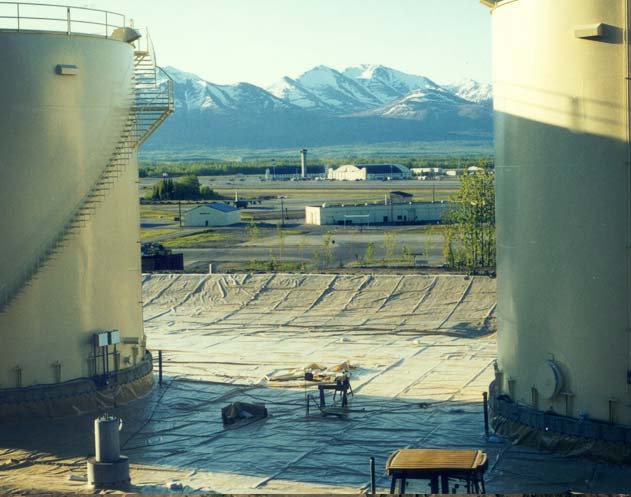

CoolGuard geomembranes are engineered for use in areas where primary and/or secondary containment of hydrocarbons, liquids, aggressive chemicals, and other regulated substances is required. CoolGuard can handle many petrochemicals in primary contact.

Utilized in the field since 1990, CoolGuard geomembranes offer a cost-effective, functional alternative to double-walled tanks, concrete-lined embankments, and similar protective structures. It is formulated with Dupont™ Elvaloy® (KEE) as part of a tri-polymer alloy, and because it is resistant to hydrocarbons and other chemicals, it fits applications where chemical resistance, high physical strength, and other unique properties are necessary.

Superior Performance and Flexibility

CoolGuard withstands a broad range of chemicals with little or no deterioration of physical properties. This superior performance coupled with the flexibility of the CoolGuard geomembrane is the result of the combination of select polymer blending, stabilizers, and the unique reinforcing mediums. CoolGuard is available with six different reinforcements, giving the designer a wide range of physical characteristics to choose from, including a “rip-stop” design. Each one offers unique properties for the application or on-site conditions.

This page contains PDF documents. If you need assistance accessing the content in these documents, please contact Cooley Group Customer Service at customerservice@cooleygroup.com

TECHNICAL INFORMATION

COOLGUARD® PW COOLGUARD® MPK36 COOLGUARD® HRL36 COOLGUARD® MPK45 COOLGUARD® HRL45

APPLICATIONS

Collapsible/Portable Tanks

Water Protection/Preservation

General Industrial and Primary/Secondary containment of hydrocarbons, liquids, aggressive chemicals, and regulated substances

CoolGuard Tanks

1 of 3

Power Plant Pond Liner & Cover

2 of 3

CoolGuard PW

3 of 3

FEATURES & BENEFITS

UV and flame resistance

Heat, RF, and wedge weldable

High abrasion/chemical resistance

Excellent outdoor service life

High resin to fabric ratio

No adhesive coats needed

High operating temperatures (250°F continuous / 275°F intermittent)

Meets FDA food requirements (21 CFR 177.2510)

Meets Dairy Industry 3A Sanitary Standards

Available in white or tan, in widths up to 144 in (365 cm)

CALL US TO SPEAK WITH A SOLUTIONS SPECIALIST

401.724.9000